In today’s rapidly evolving food industry, the definition of a “healthy factory” goes far beyond hygiene and compliance. It’s about creating a resilient, efficient and future-ready operation — one that anticipates risks, protects consumers and supports sustainable growth.

Across the food industry, data and genomics are transforming how companies understand and control the microbial world within their operations. The real question now is: how can this complex data be used to drive measurable improvements in food safety and quality?

bioMérieux is answering that question by moving beyond the test result and focusing instead on translating complex data into actionable insights for food manufacturers and processors. At its core, that means not only helping quality and safety teams identify microorganisms, but also understanding what those findings mean for cleaning, sanitation and preventive controls at the plant level.

Metagenomics with Meaning

Following its acquisition of Neoprospecta, a biotech company specializing in innovative microbiological analysis using next-gen DNA sequencing and biocomputational analysis based in Brazil, bioMérieux has expanded its expertise in using metagenomics to identify spoilage microorganisms — a critical step forward for processors focused on shelf-life stability and product consistency. bioMérieux takes this further by integrating artificial intelligence and expert analysis to interpret what the data truly reveals. This combination enables the identification of microbial trends, contamination sources and control points that traditional culture methods often miss.

Introducing the ‘Healthy Factory’ Approach

At the core of bioMérieux’s innovation is the “healthy factory” concept. By mapping the complete microbiome of a facility, bioMérieux provides a holistic picture of a factory’s microbial health. This data-driven insight helps QA leaders pinpoint risks and blind spots in monitoring programs. It’s a proactive strategy that turns microbial surveillance into predictive food safety management.

This proactive strategy encompasses the Augmented Diagnostics approach — a powerful combination of advanced microbiology, molecular biology, genomics and data science. This ecosystem goes beyond traditional testing, transforming laboratory results into actionable insights that empower teams to:

- Rapidly detect and prevent microbial risks at every stage, from raw materials to finished products.

- Trace contamination sources with precision, enabling swift root cause analysis and corrective action.

- Optimize cleaning and sanitation, reducing water and chemical use while ensuring safety.

- Minimize product hold times and avoid costly plant downtime.

Innovation in Detection: The xPRO™ Program

For those microorganisms that resist conventional detection, bioMérieux offers its xPRO™ Program. The xPRO™ Program partners with food manufacturers to tackle complex quality issues by developing customized testing solutions that help reduce spoilage, minimize waste and improve operational efficiency. This work is supported by bioMérieux’s Molecular Diagnostics and Genomics Innovation Center in Philadelphia, an innovation hub dedicated to advancing next-generation detection methods.

In an environment where both regulators and consumers expect greater assurance of safety and quality, the Augmented Diagnostics approach represents a shift from reactive testing to preventive, data-driven control. By transforming genomic data into meaningful, actionable insight, processors can move closer to a new standard of excellence: the true “healthy factory.”

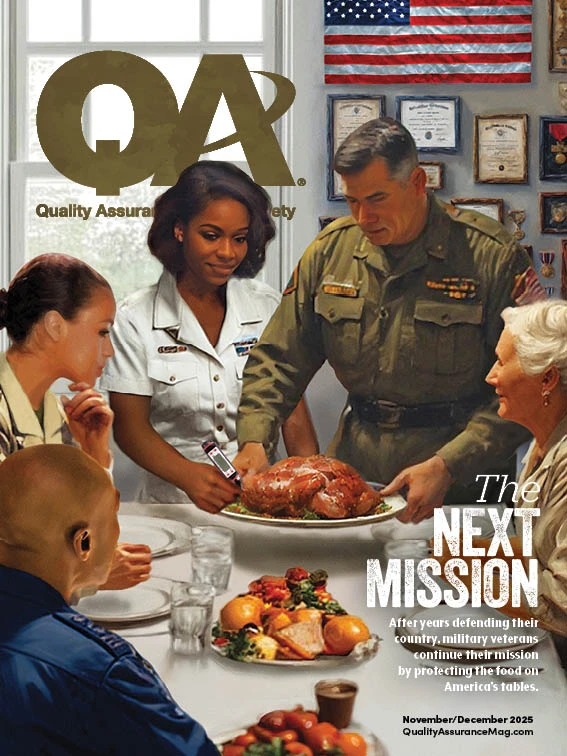

Explore the November/December 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- FDA Releases Human Food Program 2026 Priorities

- IAFNS Develops Principles to Guide Classifying Foods Based on Processing, Formulation

- New GNT Report Reveals Power of Color in Food

- Koia Enters into Clean Protein with Launch of Protein Pop

- Registration Open for USDA’s 102nd Agricultural Outlook Forum

- FDA Reports Increased Efficiency in Imported Product Reviews with New ImportShield Program

- USDA Accepting Applications for 1890 National Scholars Program

- Ambrosia Collective to Introduce Solar Foods' Solein Protein Powder to U.S. Consumers