Most food companies struggle to manage the spread of pathogens because of two key weaknesses: human inconsistency at the sink and cross-contamination from footwear. These failures leave the entire hygienic zone vulnerable and jeopardize product safety and brand integrity. If you’re a food professional that wants to secure critical contamination pathways, consider Meritech’s “Sanitize In/Scrub Out” protocol for automated and auditable hygiene.

Sanitize In: Secure Entry in Only 12 Seconds

When employees enter GMP areas, they’re stopped by turnstiles that only allow entry after they wash their hands and sanitize footwear. The CleanTech® process of our EVO systems is so efficient that it removes 99.98% of harmful pathogens from hands and footwear (when using the SoleClean attachment) in just 12 seconds.

Scrub Out: Closing the Hygienic Loop

The hygiene cycle is only complete when both entry and exit are controlled. When exiting their shift, employees pass through automated boot scrubbers that clean debris and sanitize footwear and boots up to nine inches in depth. This Scrub-Out process ensures:

- Zone Integrity: Contaminants are contained within the GMP zone, closing the hygienic loop and protecting the rest of the facility.

- Reduced Janitorial Costs: Less debris and moisture are dragged into changing rooms and hallways, leading to lower cleaning chemical usage and reduced labor hours dedicated to general sanitation.

Process Efficacy and Operational Benefits

The automated “Sanitize In/Scrub Out” loop offers quantifiable advantages that directly impact operations and help achieve financial excellence:

- Guaranteed Pathogen Reduction: 4-log reduction that removes human error and inconsistency while defending against the most critical foodborne illness outbreaks.

- Maximized Labor Efficiency: Converts a 30-second manual entry process to a guaranteed 12-second automated cycle that minimizes bottlenecks during high-traffic shift changes and immediately boosts ROI.

- Enhanced Audit Defense: Verifiable data logs of every completed hygiene event for both hands and footwear, proving adherence to SOPs, simplifying and improving compliance reporting and strengthening audit readiness.

- Low Employee Demand: Training is instant and intuitive, requires no intricate steps and doesn’t depend on consistency from distracted or rushed employees.

Quantifiable ROI as a Strategic Investment

The future of food safety requires proactive solutions. The continual work to reduce risk, especially involving human fallibility, must incorporate advanced technological support. The cost of a single product recall due to microbial contamination is astronomical, and contamination is a question of “when,” not “if.” Adopting an automated “Sanitize In/Scrub Out” methodology like Meritech is a strategic investment that will save you hundreds of thousands of dollars each year in excessive chemical costs, distressed or adulterated product and dings to your brand’s reputation.

By partnering with Meritech, you get preventative maintenance, chemical refill subscriptions and expert consultation in hygienic zone design. For more information on solutions that will best fit your facility, visit https://meritech.com.

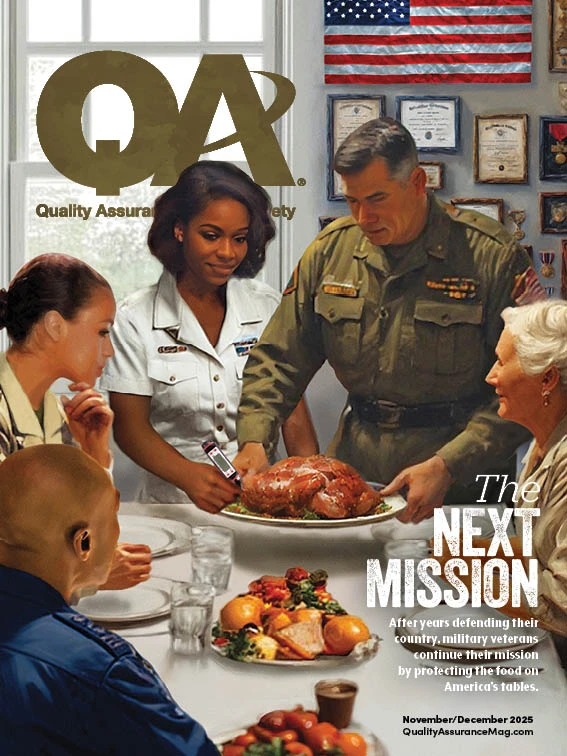

Explore the November/December 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Quality Assurance & Food Safety

- FDA Releases Human Food Program 2026 Priorities

- IAFNS Develops Principles to Guide Classifying Foods Based on Processing, Formulation

- New GNT Report Reveals Power of Color in Food

- Koia Enters into Clean Protein with Launch of Protein Pop

- Registration Open for USDA’s 102nd Agricultural Outlook Forum

- FDA Reports Increased Efficiency in Imported Product Reviews with New ImportShield Program

- USDA Accepting Applications for 1890 National Scholars Program

- Ambrosia Collective to Introduce Solar Foods' Solein Protein Powder to U.S. Consumers