In late December 2015, a multi-unit fast food owner-operator with headquarters in western Pennsylvania received an unwelcome holiday present – a wastewater surcharge fine from a local municipal water authority to the tune of several thousand dollars!

The very diligent owner-operator was shocked as none of his other locations had ever received such a fine. He was even more shocked to understand that this fine would be assessed to his location monthly, unless his Biological Oxygen Demand (BOD)* and Total Suspended Solids (TSS)** levels in his restaurant’s wastewater could be reduced dramatically.

These fines would dramatically impact the owner-operator’s bottom line! The situation, however, was not his or his employee’s fault. He had recently purchased several additional locations, including this store, which had gone through several changes of ownership within the past year. The previous owners had not been aware that these surcharges could be eliminated or reduced, mistakenly thinking they were treatment fees from the water authority.

Furthermore, this high-volume store unfortunately had a smaller-than-normal grease trap – only 500 gallons – when most commercial establishments have either 1000 or 1500 gallon traps. This store’s trap was cycling 1500 gallons of water a day. The trap had not been maintained well by the previous ownerships.

Typically, well-maintained grease traps prevent higher FOG levels from entering the municipal water system. They act as interceptors for food waste and grease from restaurants and other businesses with food service or food preparation, holding these potential pollutants in place while the normal wastewater flows through the interceptor and into the municipal sewer system. Grease traps are normally efficient systems, but require maintenance and should be regularly pumped-out by local sanitation contractors. Employees should also be trained to not overload the system with too much food debris or waste liquid added to the drains.

Our hero owner-operator in this particular instance, had inherited a two-fold problem… a busy establishment with a small trap, and a trap system that had not been pumped or well-maintained, possibly for years. This was forcing too much FOG into the municipal water lines. Municipal authorities regularly test BOD and TSS levels, and noted extremely high levels in a fourth quarter evaluation.

This location had BOD levels of 4660 mg/l and TSS levels of 580 mg/l. “Normal” BOD ranges for the water authority were 300 mg/l and TSS was 350 mg/l. The BOD levels were extremely high, which is often typical for very busy restaurants, according to one representative from the municipality.

In this situation, however, the owner-operator was both a diligent businessman and nationally recognized by his franchise. Newly aware of this situation, he and his people rapidly began to put a plan in place.

The Solution. First, he proactively contacted the municipal water authority, to better understand the issues and to seek advice and guidance. Second, he called Pelican Solutions.

From previous experience at several of his original group of stores with a Pelican product – Xpel Original – he and his managers knew that Xpel’s beneficial bacteria and surfactants worked rapidly in Fast Food drains to naturally digest biofilm (FOG). Xpel thus changes the environment where fruit flies – a pervasive nuisance in food service operations – could feed and breed, either in food prep or floor drains. With no biofilm odors to attract the pests, and no biofilm for feeding or nesting, fruit flies quickly become absent.

The owner-operator reasoned that if Xpel was effective in reducing FOG in drains, it could be effective on FOG in grease traps!

His Pelican Solutions' friends were coincidentally studying wastewater treatment data from experience with larger Food Processing operations. They rapidly provided Xpel product for a test, and offered further expertise to develop a treatment protocol.

The steps for success were as follows:

· On the advice of the water authority, the owner-operator contracted a local, reputable sanitation service to pump out the trap, and to continue doing so on a monthly basis

· He also hired a plumbing contractor to jet out the effluent line from the trap into the sewer system, to ensure the line’s normal flow was free of any grease blockage that developed over time.

The stage was now set for Xpel to begin work under better circumstances.

On a twice-weekly basis, the restaurant personnel began applying measured portions of Xpel to drains that were known to lead to the grease trap, and also to apply Xpel directly to the trap itself, through the exterior manhole cover, once weekly.

The initial plan was to treat the restaurant’s system for six weeks, with BOD and TSS levels to be checked by an independent environmental testing lab, which had previously been conducting tests at the location for the water authority.

However, because of a simple timing miscommunication, the next lab test was conducted by the water authority only three weeks into the test.

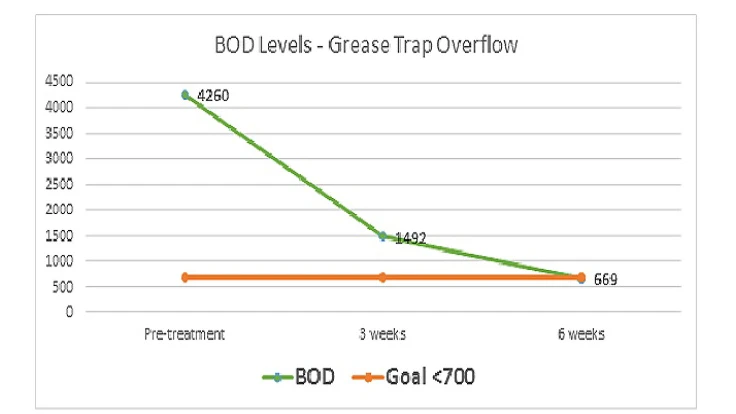

The Results. The good news, was that, after only three weeks, Xpel had already reduced the BOD level from 4260 mg/l to 1492 mg/l.

With the partnership and approval of the water authority, the Xpel protocol continued for the remaining three weeks, and another test was scheduled. This time, BOD levels were at an all-time low of 660 mg/l, and TSS levels were within the acceptable range.

The owner-operator’s proactive and efficient plan, and the subsequent results, so impressed the water authority that they rebated the latest fine, and suspended subsequent fines for six months. This saved the owner-operator thousands in fines, over and above the cost of Xpel and the pumping/line maintenance.

Added benefits included no fruit flies and no sugar snaking (clogging) of beverage drain lines.

The owner-operator and Pelican Solutions are continuing monthly tests, to further determine the most efficient application of Xpel and to regularly monitor the issue.

Net-net: another satisfied Pelican Solutions’ customer saving thousands of dollars because of Xpel, and a greener, cleaner community water system: a huge win-win overall.

Xpel Original is the effective, efficient and economical choice for drain remediation and grease trap issues. Xpel eliminates odors and breaks down biofilm. Visit www.xpelsolutions.com or call 844-GET-XPEL for more info.

*BOD is a measure of pollutants in wastewater typically monitored by water treatment authorities. If BOD levels are too high, the effluent wastewater requires additional, sometimes costly, treatment at the community water treatment plant.

**TSS is also a measure of wastewater pollution. High BOD and TSS levels are often caused by too much FOG (Fats, Oils and Grease) in the commercial establishment’s water and sewage system.

Latest from Quality Assurance & Food Safety

- Director General of IICA and Senior USDA Officials Meet to Advance Shared Agenda

- EFSA and FAO Sign Memorandum of Understanding

- Ben Miller Breaks Down Federal Cuts, State Bans and Traceability Delays

- Michigan Officials Warn Recalled ByHeart Infant Formula Remains on Store Shelves

- Puratos USA to Launch First Professional Chocolate Product with Cultured Cocoa

- National Restaurant Association Announces Federal Policy Priorities

- USDA Offloads Washington Buildings in Reorganization Effort

- IDFA Promotes Andrew Jerome to VP of Strategic Communications and Executive Director of Foundation