Heat and Control

LAS VEGAS – Heat and Control, Inc., a global equipment manufacturer and food processing industry supplier, will exhibit at Pack Expo Las Vegas (PELV) 2025 in Las Vegas Sept. 29 to Oct. 1, located at Booth #W-2506.

Process Water Recirculation and Freshwater Reduction

Today’s environmental and sustainability benchmarks demand new food processing resource management and equipment design approaches. Heat and Control’s new Cascade Water Recirculation is designed to help food processors reduce up to 75% of freshwater consumption without compromising product quality or equipment reliability, said the company. To achieve this, Heat and Control brings two key components to the design table: Slice Wash Support Module (SWSM) and Process Recirculation Support Module (PRSM).

Cascade water recirculation advantages include:

- Reduced freshwater consumption

- Reduced energy consumption

- Improved process performance

- Improved sanitation

Visitors can learn more about Cascade Water Recirculation at the Processing Innovation Stage (N-9100 North Hall) on Monday, Sept. 29 from 1–1:30 p.m. PST. Jonathan Kaylor, Heat and Control development engineer, will share insights about process water recirculation and freshwater reduction for the food industry.

Heat and Control will also showcase the latest and innovative solutions for processing, seasoning, conveying, weighing, packaging and inspection, said the company. Heat and Control brands, together with partners Ishida and CEIA, will display a variety of equipment and have experts on hand to discuss your production needs.

Fugitive Dust Minimizing Seasoning Applications

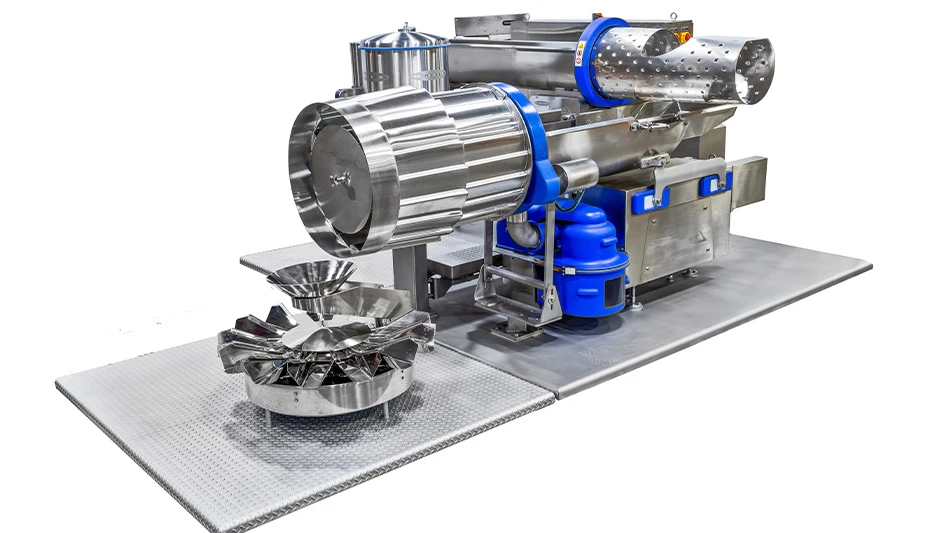

Spray Dynamics Symphony In-Kitchen Seasoning System (IKS) and FastBack Symphony On-Machine Seasoning System (OMS) feature an integration of seasoning ingredient capture and containment and application consistency technologies. This solution significantly prevents seasoning ingredients, which are potentially hazardous for operators, from becoming airborne, ensures seasoning ingredients are targeted to the product, and reduces waste, said Heat and Control. See both Spray Dynamics Symphony IKS and FastBack OMS Systems in action at PELV 2025.

Ishida VFFS High Speed Snack Packaging

The latest in high performance and high speed from Ishida, the new Inspira Series high speed bagmaker can run up to 220 small bags per minute, said Heat and Control. The rotary motion bagmaker ensures seal integrity at high speeds and with various film types, said the company.

View a broad range of metal detection equipment at our booth including the next evolution of CEIA metal detection systems. The systems deliver extremely high detection sensitivity for metals for all manner of food products, anywhere along the line, said Heat and Control.

For more information, visit https://www.heatandcontrol.com/event/pack-expo-las-vegas-202.

Latest from Quality Assurance & Food Safety

- FDA Releases Produce Regulatory Program Standards

- Invest in People or Risk the System: Darin Detwiler and Catalyst Food Leaders on Building Real Food Safety Culture

- USDA Proposes Increasing Poultry, Pork Line Speeds

- FDA Releases New Traceability Rule Guidance

- TraceGains and iFoodDS Extend Strategic Alliance

- bioMérieux Launches New Platform for Spoiler Risk Management

- SafetyChain Receives SOC 2 Type 2 Certification

- Puratos Acquires Pennsylvania-Based Vör Foods