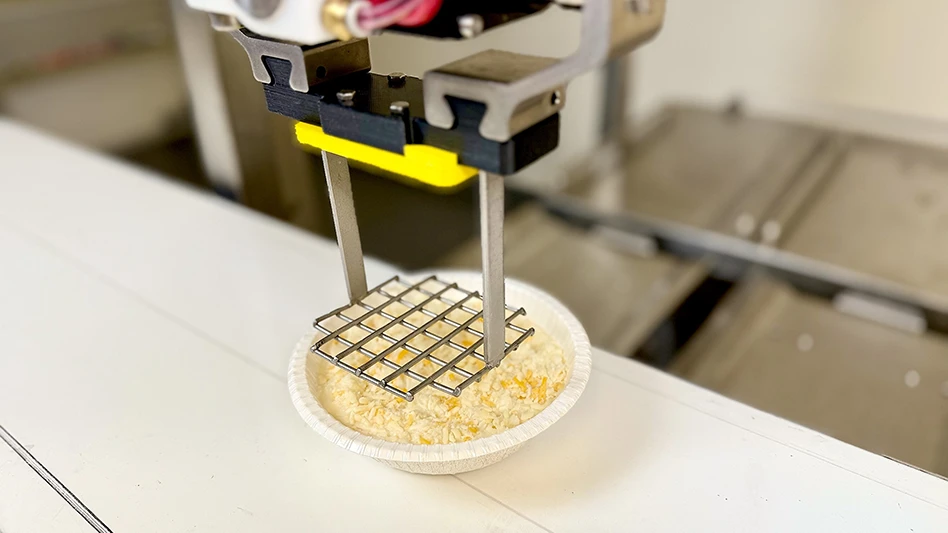

Photo courtesy Chef Robotics

SAN FRANCISCO — Chef Robotics, a company specializing in AI-enabled robotics for the food industry, announced its new pat-down capability. Chef robots can now "pat down" or "tamp down" ingredients inside prepared meal trays before sealing, enabling food manufacturers to automate a spreading and flattening task. The capability improves meal presentation, reduces tray-sealing issues and minimizes food waste while allowing manufacturers to reduce labor costs, said the company.

When workers deposit ingredients into meal trays, the ingredients naturally settle in the center, creating an uneven, bulging appearance, said Chef Robotics. This leads to spillage during tray sealing, limited space for other ingredients and compromised product aesthetics, the company said. To achieve uniform coverage before sealing, manufacturers often rely on line workers to manually flatten food inside each tray.

Chef’s new pat-down capability fully automates meal flattening tasks using vibration technology in the end effector along with a flat, cross-slotted utensil. This new utensil is interchangeable with Chef's depositing utensils and features a cleanable, rounded-edge design that meets food safety standards and cleaning protocols, said the company. The solution employs AI-powered computer vision software to detect and track trays on the conveyor in real time, understanding their position and orientation. This detection capability enables robots to handle variations in tray positions, line stoppages and speed changes that traditional automation cannot manage, said Chef Robotics.

For high-volume operations, the pat-down capability integrates with Chef's robot-to-robot (R2R) coordination system, enabling multiple robots to coordinate and distribute tasks by alternating trays for increased throughput. Production lines can also use robots for both meal assembly and pat-down operations simultaneously, with one robot depositing ingredients while another flattens meals.

The pat-down capability is designed to eliminate a strenuous, repetitive task, said Chef Robotics, freeing up workers for higher-value tasks while reducing overall production costs and preventing repetitive stress injuries. Beyond labor cost reduction, the solution addresses downstream operational challenges such as spillage during sealing, machine downtime, rejected trays and food waste, said the company.

The capability is now widely available to food manufacturers in the U.S., Canada and the UK.

Latest from Quality Assurance & Food Safety

- New Strain, More Illnesses Reported in Moringa Leaf Powder Salmonella Outbreak

- Kiwa ASI Expands Canadian Presence with Addition of TSLC

- Samples Collected by FDA Test Positive for C. Botulinum in ByHeart Infant Formula Investigation

- FDA Releases Total Diet Study Interface

- Wisconsin Cheese Makers Association Offers Student Scholarships

- Mandy Sedlak of Ecolab on Building a Career in Food Safety and What’s Next for the Industry

- Kroger Shares 2026 Food Trend Predictions

- USDA Announces New World Screwworm Grand Challenge