Handmade. It’s a term that elicits visions of an individual painstakingly creating one-of-a-kind, premium items, so that even if a row (or pallet) of the “same” items is made, each will have its own individual stamp of distinction.

Handmade. It’s a term that elicits visions of an individual painstakingly creating one-of-a-kind, premium items, so that even if a row (or pallet) of the “same” items is made, each will have its own individual stamp of distinction.

That is exactly the experience that The Cheesecake Factory Bakery wants its customers to have of its products, and the reason it not only resists a great deal of automation in its operations, but actually tried a few new technologies and went back to manual.

That’s not to say that the operations of the bakery for the world-famous restaurant chain are in any way antiquated, rather, it has learned to be very selective in where, how, and why it applies new technologies.

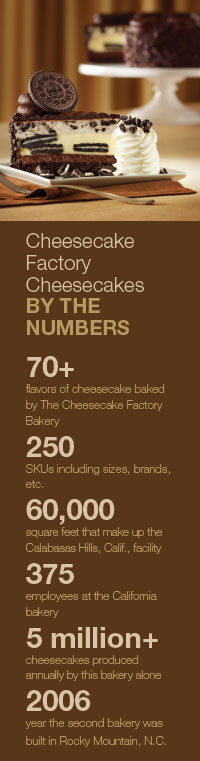

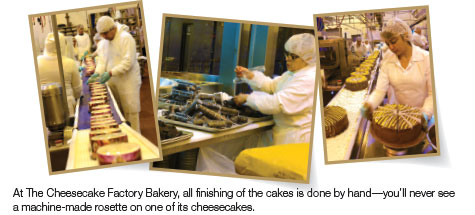

All finishing of the cheesecakes is done by hand—you’ll never see a machine-made rosette on a Cheesecake Factory Bakery cheesecake. And for the Oreo Dream Extreme, the sandwich cookies are purchased in the 12-sleeve-sized boxes, just like those that a large family (or Oreo lover) would buy at a warehouse store. This is because the bakery uses only whole Oreos in its cheesecake layers—whole Oreos that are placed by hand.

On the other hand, the company doesn’t eschew technology. Electronic tracking is used to label and track all items from incoming goods to finished product. The company incorporates state-of-the-art processing technology for mixing, baking, and freezing. But at both bakeries, finishing, Oreo placement, and other such manual perfection is still done only by hand.

“Everything is hand decorated, so no two cakes are ever alike,” said Director of Food Safety and Quality Assurance Iris Galanis Eshoo. For example, assembly of Oreo Dream Extreme Cakes includes automated dispersal of cheesecake batter, then manual placement of six whole Oreos, smoothing of the batter over the Oreos, and loading onto racks to be placed into the ovens.

For the bakery’s 30th anniversary, the Oreo Dream cake has been made Extreme through the addition of a fudge layer between the layers of cake—hand applied, of course. Similarly, finishing of the Reese’s Peanut Butter Chocolate Cake Cheesecake involves automated dispersal of the specified amount of icing onto a cake, after which it is all manual—icing of the top and sides of the cake, placement of the cake into an twelve-slice cutter, replacement of any small slices, smoothing of the icing after slicing, patting of chocolate chips around the cake, creation of rosettes perfectly centered on each slice of cake, and packing of each cake into an individual box.

Or, in brief, the cakes are frozen, depanned, iced, sliced, decorated, and packed—by hand.

Maintaining manual perfection isn’t easy, but long-tenured, passionate workers; “gold” standards; and a tradition of excellence that dates back to the founders all help to make The Cheesecake Factory Bakery a Gold Standard itself.

A Quality Heritage. The company was founded 32 years ago by “a little couple who loved what they did,” said President Max Byfuglin of founders Oscar and Evelyn Overton. “Evelyn didn’t know what quality assurance was, but she was quality assurance.” (See A Favorite Since the 50s, sidebar below)

She also was innovative. Evelyn was one of (if not the) first to put ingredients into cheesecake—and freeze it. There was plenty of resistance and “You can’t do that!” but Evelyn persisted and proved that you could indeed “do that” and do it well.

The Cheesecake Factory Bakery’s President Max Byfuglin, Production Manager Omar Vasquez, Quality Assurance Manager Daryl Roper, Food Safety and Sanitation Manager Brian Farinha, and Director of Food Safety and Quality Iris Galanis Eshoo with a portrait of the company’s founders, Oscar and Evelyn Overton. Photos by Bruce Morr Photography. The Cheesecake Factory Bakery’s President Max Byfuglin, Production Manager Omar Vasquez, Quality Assurance Manager Daryl Roper, Food Safety and Sanitation Manager Brian Farinha, and Director of Food Safety and Quality Iris Galanis Eshoo with a portrait of the company’s founders, Oscar and Evelyn Overton. Photos by Bruce Morr Photography. |

Such non-traditional quality assurance continues today. “It’s a blend of traditional and modern ideas that drive quality in our organization,” Byfuglin said, with many of the bakery’s quality and employee-welfare practices following such lines, including its:

- Pre-shift calisthenics. Doing so much work by hand means a great deal of repetitive motion for some and heavy lifting for others. To counter this, the beginning of each shift includes a brief period of micro-stretch exercises. Although employees were a bit reticent the first time this was done, it has become a standard that is now simply part of the day.

- Gold standard cakes. Because the bakery has more than 70 different cheesecakes, workers are not expected to remember the exact specifications of each cake. Rather, prior to start of work, a Quality Huddle is held on the finishing line. The specifications and assignments are discussed, during which a “gold standard cake” is assembled and decorated. “Most people are visual,” Galanis said. “If you have a picture in front of you, it’s easier to make a same-looking cake.”

- Baked from scratch. No mixes, pre-crumbed crusts, or pre-made anything is allowed in Cheesecake Factory cheesecakes. Everything is made from scratch, from the mixing of the batters to the shaving of the chocolate.

- Cross-training and rotation. While this practice may not be unique, rotating between icing and slicing or rosettes and shaved chocolate is not a typical industry shift—or training session. To keep workers fresh and fervent in their work, key positions are rotated every hour or two depending on the intricacy or difficulty of the job, said Production Manager Omar Vasquez.

- Surrounding awareness. The plant’s regular safety meetings include a monthly theme. Because the plant is crowded and there are a lot of moving parts, December’s Monthly Safety Topic of Surrounding Awareness was intended to remind workers to be aware of their surroundings as they move through the plant. For example, the cake racks are very tall, so when one needs to be moved, the worker should first do a check to make sure no one is standing behind it. Same for the huge bowls that contain 1,000 pounds of batter. “Once these are in motion, they are hard to stop,” Galanis said. The focus has not only led to year-over-year improvements in worker safety, but also resulted in a record 225 injury-free days. “It’s critical that the staff understands why they do what they do, and if they don’t, what are the consequences,” Galanis said.

- Involvement and celebration. Having weekly topics and monthly safety meetings can quickly become rote, so the bakery works to keep things fresh by including fun activities and give-aways during the sessions. “We get the staff involved and thinking safety,” Galanis said. Workers are also involved in decision making on new initiatives, she said. “Every time we think of a new initiative, we go to the floor and get buy-in.”

- Certification badges. Although a key quality focus of the company is the individualism of handmade cakes, it is just as critical that each cheesecake meet consistent baking specifications. As such, employees who are responsible for reviewing recipes, approving equations, and conducting other such calculations must be certified in each area and annually recertified. Once certified, the employee receives a badge with name, photo, and listing of each qualification, “licensing them to perform the function,” Galanis said. It is a badge the workers take pride in wearing.

In both quality and safety, Vasquez said, “We look at the industry standard, but we hold ourselves to higher standards than those. The industry has some sort of margin of error, but we don’t.”

|

Achieving Double Golds in Pest Management As a twice-medaled recipient of the Gold Medal IPM Partner Award presented by Orkin, The IPM Institute of North America, and NSF, The Cheesecake Factory Bakery’s pest management program is a strong example of its overall food safety focus and strength. In 2006, the bakery was one of eight winners, and in 2010, it was again recognized as one of four winners, who were selected for their commitment to Integrated Pest Management partnerships. As stated in the 2010 award announcement, “The company’s strong commitment to excellence and focus on food safety and proactive Integrated Pest Management (IPM) practices have earned the facility its second Gold Medal IPM Partner Award.” The release also included recognition of bakery employees, “who uphold the highest safety standards to ensure complete customer satisfaction.” Receiving the award twice is a significant achievement because the judging becomes incrementally tougher each year, said Orkin Region Manager Machelle Stockstad. Expert judges assess of sanitation, maintenance, training, and other IPM criteria, but, Stockstad added, they also look at subtle details that enable a pest-free environment without using pesticides as a first-choice solution. Facilities are nominated for the award by the local Orkin branch personnel, with more than 60 facilities in contention. There is no single process or action that enables one to achieve Gold Medal IPM, rather, as Stockstad explained, “There is a combining of a number of IPM steps to achieve pest prevention in each area.” The bakery’s true partnering in pest management is another key factor in its quality IPM, said Commercial Assistant Branch Manager Bryn Coffman. “Communication is what makes the partnership work,” she said, adding, “I truly feel like a partner here, rather than a vendor.” The bakery’s focus on continuous maintenance and exclusion work is also significant in keeping cracks sealed and pests out. As Stockstad said, referring to the state’s frequent earthquakes, “In California we move around a bit, so that’s important.” |

This isn’t to say that the bakery expects perfection in every step, but that steps are taken to ensure perfection in the final result, Galanis explained. “We know the equipment is not perfect, and the cakes are so large that we expect some variance, so we have ways of correcting that.”

Much of this correction is also manual, with visual inspections conducted at each step, batter viscosity tested, temperatures checked, crumb density verified, and management walking the facility multiple times during shifts to prevent issues before they can become a concern, she said.

Food Safety Gold. While non-traditional may be a good description of the bakery’s quality practices, preventive is a better description of its food safety practices, for which it also strives to meet a gold standard. It is this goal that ensures the bakery is prepared for the Food Safety Modernization Act. “We’re already above the standard, so we’re pretty much ready for any changes that come,” said Quality Assurance Manager Daryl Roper. In fact, he added, “It’s about time that they set some hard rules, but we’re not concerned about what those will be.”

Included among the bakery’s gold standard food safety practices are:

- Sanitary package decasing. Many ingredients are received with at least double wrapping. The exterior layer is removed before the package is brought into the baking area, so only the inner, protected layer comes anywhere near open ingredients. Once a package is emptied, every piece of packaging is accounted for to ensure not a single shred of paper or plastic accidentally falls into a mix.

- No Wooden Pallets. The bakery has metal detectors on each line, but does not use X-ray, so no wooden pallets are allowed in the plant. Although many ingredients are shipped to the bakery on wood, they are moved to plastic pallets at the bakery. This also reduces the potential of wood-borne pests and bacteria being brought in. (See Achieving Double Golds, table at the bottom, for more on the bakery’s pest management program.)

- Receiving. Although having a single delivery door could be a deemed a disadvantage for some, at this bakery it is seen as an advantage and a means of tighter control. But it is in no way the only means of ensuring safety of incoming goods. When a truck arrives at the dock, a UV-light inspection of the truck is conducted for cleanliness, and sensors are checked to ensure proper temperatures were maintained. “We won’t unload a truck unless all the minimum requirements are met,” Galanis said. The bakery also has a vendor management program, for which it visits supplier facilities, requires HACCP programs and third-party audits to GFSI standards, inspects certificates of analysis, pulls samples for internal micro testing validation, and tags and tracks all lots from incoming ingredient to finished product. “From a program standpoint, we do a great job with traceability,” she said.

- Finished goods. The bakery employs a positive-release program, micro testing every lot of finished goods prior to releasing it. It also conducts daily product cuttings: Each morning, sample cakes made the day before are defrosted, and at 10 a.m., a tasting team meets to assess factors such as performance, appearance, and taste. “People eat first with their eyes, so it has to look beautiful,” Galanis said. Only when the samples have passed these finished goods tests is a lot released for distribution.

- Allergens. With regular use of six of the eight major allergens, the bakery color codes all allergenic ingredients. It places particular emphasis on segregation of peanuts and tree nuts, because the others (milk, eggs, wheat, and soy) are common to all their cheesecakes.

Focus on the People. Whether it is the employee-focused practices, the sweet sugared air, or something else, the passion and cheerfulness of The Cheesecake Factory Bakery employees is noticed by others as well. Byfuglin was once asked about this by the owner of a neighboring company. “What’s happening over there—are you guys drinking Kool-aid?” Byfuglin was asked. Although he laughingly related the story, Byfuglin noted the truth in it as well—“In some ways we are. It’s this pride thing that’s here.”

Many companies strive for employee job satisfaction, but The Cheesecake Factory Bakery sees job happiness as an essential component of its quality. “We make products that make people smile when they eat them. If we keep employees happy, the customers will be happy.”

One way that the bakery maintains this happiness, which is also shown by its less than three percent employee turnover rate, is through feedback—both positive and constructive. “When we win, we win as a team. And when we win, we celebrate,” Vasquez said, adding, “We are very good at celebrating.”

Selective Technology. The Cheesecake Factory Bakery’s processing technology has evolved over the years, starting with a pizza oven that Evelyn used for the first cheesecakes and a freezer room, and graduating to advanced baking and freezing equipment. Along the way, trial and error has resulted in certain key steps remaining handmade, while others were found to be better suited to varying levels of automation. Since then, the company has been more selective in incorporating new technologies, and has learned, through the years, where technology and automation can aid in quality and where manual tasks are better left alone.

From these lessons learned, and to better serve customers in the Eastern U.S., The Cheesecake Factory Bakery built its second plant in Rocky Mount, N.C., in 2006. At this new state-of-the-art facility, Byfuglin said, “We applied everything we knew.”

But, even while incorporating new baking technology at the two facilities for improved consistency, the finishing is and will remain manual. “There are machines that will put perfect rosettes on each cake, but that’s not us,” Byfuglin said. “Hands-on finishing—it’s a mantra for us.”

It is a matter of carrying on the tradition of the founders and “watching the tiny changes,” he added. “We are very protective of the genuine historical identity of our cakes, and are extremely careful about modifications. We only act after thorough evaluation to ensure there is no detrimental impact. This is true for ingredients and equipment.” In fact, it is this big-picture, long-term focus that dictates all decisions and practices at The Cheesecake Factory, and has enabled it to build upon its reputation year over year. “Knowing that we have such a reputation for quality, both internally and externally, we have to have people who focus on that,” Byfuglin said. “They have to be ‘on’ every single moment of every single day—and more. You have to instill that in people.”

As validated by Byfuglin, who said, “Iris dedicates her life to the bakery,” it is a value that is thoroughly instilled in Galanis and passed along to her team.

“There’s nothing better than working for a company whose product you love and brand you believe in,” Galanis said. “We don’t just hire people with degrees to manage our food safety and quality, we hire people who have a drive and passion for what they do.”

“It’s a labor of love,” Byfuglin added. “Love for the people, love for the cakes.”

|

A Favorite Since the 50s When Evelyn and Oscar Overton dreamed of having a successful family business, Evelyn’s passion for baking led to the creation of an original cheesecake—that became a hit with all who tried it. In the early 1950s, Evelyn converted their basement into a professional bakery and began supplying cheesecakes to local Detroit restaurants. In 1972, the Overtons decided to move and open a small bakery in Los Angeles. They called it The Cheesecake Factory. It was son, David, who had the idea to open a restaurant of the same name in 1978, said President Max Byfuglin. Afraid that they‘d be slammed at lunch on opening day, David, now CEO, put out a sign that the restaurant would open at 2:00 p.m. “That‘s when the line started, and it hasn‘t stopped since,” Byfuglin said. It is a line that continues to carry the company into global waters. Its first international restaurants opened in 2012 in Kuwait and Dubai, where waits of more than five hours are not uncommon. |

The author is Editor of QA magazine. She can be reached at llupo@gie.net.

Explore the February 2013 Issue

Check out more from this issue and find you next story to read.

Latest from Quality Assurance & Food Safety

- Food Safety Summit Keynote Focuses on Food Safety Leadership

- FDA Publishes Landmark Final Rule to Enhance the Safety of Agricultural Water

- The Wendy's Company Reports 2023 Corporate Responsibility Progress

- Local Bounti Opens New Controlled Environment Agriculture Facility

- Tröegs Partners with Patagonia Provisions to Introduce Kernza Lager

- Neogen Launches New Molecular Method for Detection of Two Salmonella Serotypes

- Standard Meat Company Appoints Keith Blanks as Chief Commercial Officer

- USDA Finalizes Policy to Protect Consumers from Salmonella in Raw Breaded Stuffed Chicken Products