Source: Readex Research; Respondents: 108

The Big Three that food processing facilities do not want to invite into their operations are flies, rodents and cockroaches, which, by nature, introduce filth and the potential for disease. It’s already in their bloodstreams.

“Cockroaches are competent vectors of disease by mechanically transferring unwanted pathogens from where they live,” said Dan Collins, noting that FDA and health departments recognize them as a threat to public health. Collins is president of Independent Pest Management Consulting in Evansville, Ind., and he works with food and beverage facilities to develop and implement pest management systems.

When cockroaches are present, companies in this industry have a real problem. Collins describes a case when a facility nearly lost a $50 million deal because the customer visited and found cockroaches present. “We spent three weeks crawling through every part of the facility and we got them under control, but we worked our tails off,” he said. “You can lose lots of business, get shut down, fail a third-party audit and land on the news with mud on your face. It’s a publicity nightmare.”

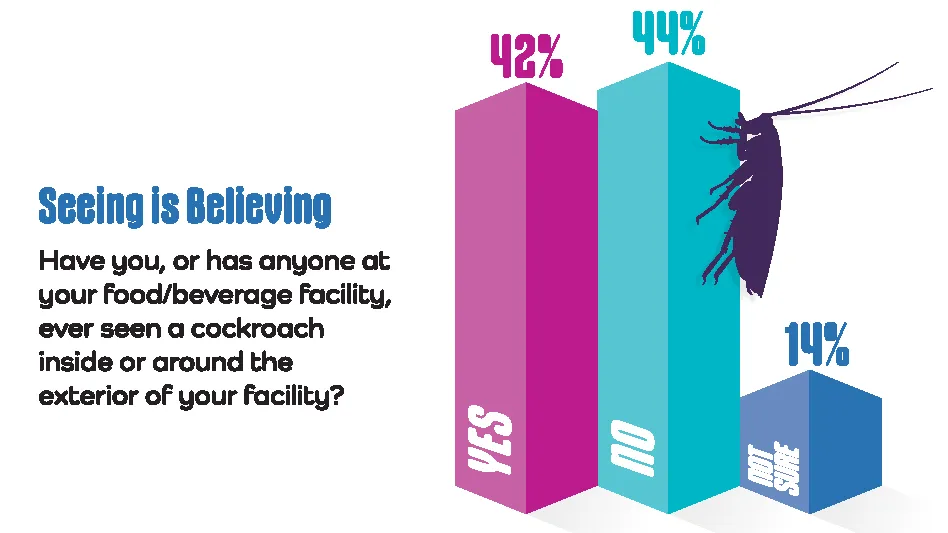

While 97 percent of respondents to QA magazine’s annual State of the Cockroach Market survey feel their facility’s cockroach control programs are successful, 42 percent said they have seen a roach inside or outside of their facility.

One leads to many more, along with a dirty problem to deal with. “They’re not like other animals like raccoons that will wash their hands before they eat,” said Scott Green, an associate certified entomologist and technical service manager for Rentokil Terminix. “Cockroaches don’t care. They like to reside in filth areas because it’s where other humans or predators will not go to find a food source.”

Green said cockroaches are opportunistic and problematic from a health standpoint because of their own habits and where they come from.

The key for food and beverage processors is to identify harborage hot spots, eliminate conducive conditions and partner with a pest professional to monitor, control and prevent cockroach pressure.

“Food production facilities should not accept any cockroaches into their facilities,” Collins said. “It’s not acceptable.”

Harborage Hot Spots. Cracks and crevices, wet wash areas, employee lockers and break rooms — these are some common “hangouts” for cockroaches. “The main things to look for are wood, water and warmth,” Collins said, calling those conditions “The Three Ws.”

A company’s sanitary procedures can actually invite cockroaches to nest. For example, wet wash facilities that use high-pressure water and steam to clean floors, walls and other surfaces usher food into hard-to-reach or inaccessible areas.

Collins describes a potential scenario at a dairy facility. “They do a heavy wash and there’s a crack in the floor or up against a wall, and they end up pushing that residue into a perfect void for cockroaches to develop,” he said.

One bakery he serviced had a production line where product dropped about 10 inches from the oven outlet to a conveyer system. “You can imagine the debris coming off of that,” Collins said, adding that a system retrofit solved the issue.

Intercompany transfers of equipment and materials are also an entry point and often overlooked. “For example, you are taking an oven from a bakery in Indianapolis to the location in Chicago. One has a cockroach problem and the other doesn’t,” Collins said. You know what happens next.

Catch basins, grease traps and drains are other appealing places for cockroaches to develop. Green points out another unexpected hot spot: appliance insulation. Deliveries of ingredients and products also can drop off unwanted pests.

How cockroaches enter depends on the type, too. American cockroaches tend to stay outdoors, though they can work their way inside. “American cockroaches typically come in through sewer systems, water systems or steam tunnels — through utilities,” Collins said. “They are more mobile than German cockroaches and can come in from 100 feet away.”

German cockroaches tend to travel no farther than 10 to 15 feet. “They are typically introduced via workers,” Collins said. Respondents to the QA survey indicated that employee belongings (27 percent) and food/ingredient deliveries (23 percent) were ways cockroaches enter. Thirty-three percent suspected cockroaches come from the outside, and only 7 percent said non-food deliveries were a culprit.

Especially now, with labor shortages and more temporary employees, Collins sees lax uniform policies and the transient nature of the workforce as reasons why cockroaches are more likely to come in. “Companies are allowing personal items on production floors,” he said.

Building design also comes into play. Newer food plants are constructed with “sanitary design,” Collins said. “They are able to design equipment that is elevated off of the ground, and there are not a lot of seams and crevices where cockroaches can get inside equipment. In older facilities, we have to look at how to seal up harborage points.”

Awareness & Strategy. To find areas where these pests live, “You have to think like a cockroach,” Collins said.

A thorough risk assessment of a facility can uncover conducive conditions. An assessment should identify the facility’s age, construction materials, master cleaning schedule, employee practices (uniform policies, etc.) and building design, among other factors like utilities and sewers.

“What is the root cause?” Collins said. Then, monitoring systems can help reveal high-pressure areas so pest management efforts can be focused on those spots. Collins likens it to fishing. “I only fish about 10 percent of the lake, because that is where the fish are,” he said.

Monitors should be labeled and mapped out and data gathered to identify trends. In partnership with a pest management professional, food and beverage facilities can develop and implement a comprehensive program.

Already, most work with an outside specialist — 65 percent of survey respondents rely on a pest control company for control, 6 percent assign the responsibility to an in-house department and 30 percent rely on both.

Awareness is imperative, Green added. He notices more attention and understanding toward pest management in the food and beverage industry than a decade ago. “Especially on the QA side, we are seeing them monitoring on their own and keeping trending reports to use as a comparison point,” he said, relating that this information can help guide pest management professionals’ visits. “If anything, it makes us better and more accurate.”

Download the Full Report Here

Explore the March April 2023 Issue

Check out more from this issue and find you next story to read.

Latest from Quality Assurance & Food Safety

- FDA Issues Update on Post-Market Assessment of Tara Flour

- ASI Announces Training Partnership with Rootwurks

- Nfinite Nanotech Closes $6.5 Million Seed Financing to Create Flexible Food Packaging with Nanotechnology

- University of Pretoria Food Science Student Wins IFT and PepsiCo’s Academic and Travel Undergraduate Hybrid Scholarship

- Kraft Natural Cheese and Shawn Johnson East Celebrate Launch of Kraft Signature Shreds

- Natural Sourcing International Announces Voluntary Recall of Black Chia Seeds

- PTNPA's DC Fly-In Connects Members with Policymakers

- Breck Partners Acquires NPX One