How Cold Plasma Technology Can Combat Food Safety Risks

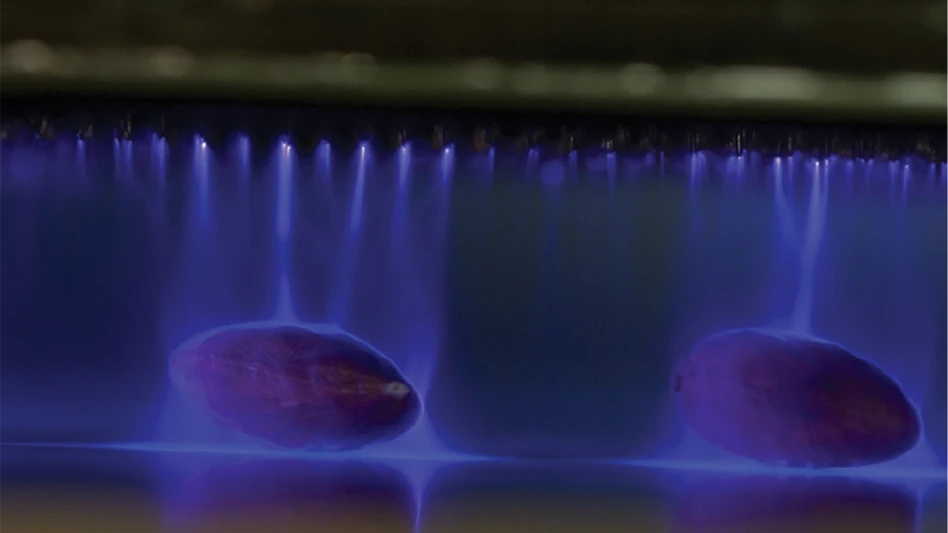

Dr. Brendan Niemira, pioneer of the cold plasma technology movement, shares how the novel technology can be applied to food products and food contact surfaces alike to combat microbial contamination risks.